What Are The Parts Of A Bathtub Faucet Called: Diagrams Explained

Understanding the anatomy of a bathtub faucet is beneficial for homeowners, plumbers, and anyone involved in bathroom renovations or repairs. Knowing the names and functions of each component allows for accurate diagnosis of problems, effective communication with professionals, and confident completion of minor repairs or replacements. This article provides a comprehensive overview of the various parts of a bathtub faucet, accompanied by explanations of their roles and potential issues. Different types of bathtub faucets exist, but many core components remain consistent across designs. This analysis will cover the fundamental parts found in most common bathtub faucet configurations.

Bathtub faucets, at their core, are designed to deliver water at the desired temperature and flow rate into the tub. The selection of materials, design complexity, and installation method can vary significantly; however, the fundamental principle of water control remains the same. This article will primarily focus on standard two-handle and single-handle bathtub faucets, as they represent the most common types encountered in residential settings. Specific variations, such as Roman tub faucets or deck-mounted faucets, will be briefly mentioned when component differences arise.

Essential Components for Water Delivery and Control

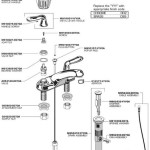

The primary function of a bathtub faucet is to regulate the flow of water from the supply lines into the tub spout. This involves several key components working in concert. These components include the handles or levers, the valve bodies, cartridges or stems, and the spout itself. Each plays a crucial role in the overall functionality of the faucet.

Handles/Levers: These are the user interface for controlling the water flow and temperature. In a two-handle faucet, there are separate handles for hot and cold water. Turning the handles opens and closes the valves, allowing water to flow from the respective supply lines. Single-handle faucets combine temperature and flow control into a single lever. Moving the lever left or right adjusts the temperature, while lifting or lowering the lever adjusts the flow rate. The handles are typically attached to the valve stems or cartridges via screws or other secure fastening mechanisms. Wear and tear on the handles themselves is relatively uncommon, but loose screws or stripped threads can cause the handles to become wobbly or detached. In such cases, tightening the screws or replacing the handles may be necessary.

Valve Bodies: These are the core structures of the faucet, housing the working parts that control the water flow. They are typically made of brass or other corrosion-resistant materials. The valve bodies are connected to the water supply lines, either directly or through flexible supply tubes. Within the valve body resides either a stem or a cartridge, depending on the type of faucet. The valve body contains internal waterways that direct the water flow based on the position of the stem or cartridge. Leaks originating from the valve body itself are often indicative of corrosion, cracks, or failed O-rings. Replacing the entire valve body may be necessary in these situations, often requiring professional plumbing assistance due to the need to disconnect and reconnect the water supply lines.

Stems (for Compression Faucets): Compression faucets, one of the older types, utilize stems with rubber washers at the end. Turning the handle rotates the stem, compressing the washer against a valve seat to shut off the water flow. When the handle is turned in the opposite direction, the stem retracts, lifting the washer away from the valve seat and allowing water to flow. Compression faucets are prone to leaks if the rubber washers become worn, cracked, or stiff. Replacing the washers is a common repair for this type of faucet. Valve seats can also become corroded or damaged over time, requiring a specialized tool to resurface or replace them. Compression faucets are generally less expensive than other types but require more maintenance due to the wear and tear on the washers.

Cartridges (for Ceramic Disc, Ball, and Cartridge Faucets): Cartridge faucets, including ceramic disc, ball, and cartridge-style faucets, use cartridges instead of stems. Cartridges are self-contained units that control water flow and temperature through internal chambers and ports. Ceramic disc faucets use ceramic discs that slide against each other to regulate water flow. Ball faucets use a slotted ball that rotates within the valve body. Cartridge faucets use a plastic or metal cartridge with internal seals. Cartridges are generally more durable and less prone to leaks than stems, but they can still fail over time due to mineral buildup, wear, or damage to the seals. Replacing the cartridge is usually a straightforward process, involving removing the handle, retaining clip, and then pulling out the old cartridge. Selecting the correct replacement cartridge is crucial to ensure proper fit and functionality.

Spout: The spout is the outlet through which the water flows into the bathtub. It is typically a curved or angled pipe made of metal, often chrome-plated for aesthetic appeal and corrosion resistance. The spout is connected to the valve body or a separate diverter valve. Some spouts are designed with a threaded connection, allowing for easy removal and replacement. Others are soldered or brazed onto the valve body, requiring more extensive plumbing work to replace. The spout may also incorporate an aerator at the tip, which mixes air into the water stream to reduce splashing and improve the perceived water pressure. Mineral buildup can clog the aerator, reducing water flow. Regularly cleaning or replacing the aerator can resolve this issue.

Understanding Diverter Valves and Their Components

Many bathtub faucets include a diverter valve, which allows the user to switch the water flow between the tub spout and the showerhead. The diverter valve is typically located on the tub spout or on a separate handle. There are several types of diverter valves, each with its own mechanism for controlling the water flow.

Diverter Knob/Handle: This is the user interface for activating the diverter valve. It is typically located on the spout itself, or as a separate handle near the faucet. The diverter knob or handle is connected to the diverter mechanism, which redirects the water flow. Over time, the diverter handle can become stiff or difficult to operate due to mineral buildup or corrosion. Lubricating the diverter mechanism with a silicone-based grease can often resolve this issue.

Diverter Mechanism: The diverter mechanism is the internal component that redirects the water flow. There are several types of diverter mechanisms, including lift-rod, tee, and rotating diverters. Lift-rod diverters use a rod that is lifted or lowered to block the water flow to the tub spout and redirect it to the showerhead. Tee diverters use a sliding valve that directs the water flow to either the tub spout or the showerhead. Rotating diverters use a rotating valve that redirects the water flow. Diverter mechanisms can fail due to mineral buildup, wear, or damage to the seals. Replacing the diverter mechanism is usually a straightforward process, but it requires identifying the correct replacement part.

Diverter Valve Body: The diverter valve body houses the diverter mechanism. It is typically made of brass or other corrosion-resistant materials. The diverter valve body is connected to the valve body of the faucet and to the shower arm. Leaks originating from the diverter valve body are often indicative of corrosion, cracks, or failed O-rings. Replacing the entire diverter valve body may be necessary in these situations, often requiring professional plumbing assistance.

Additional Components and Considerations

Beyond the core components, several other parts contribute to the overall functionality and installation of a bathtub faucet. These include escutcheons, O-rings, and supply lines.

Escutcheons: These are decorative plates that cover the holes in the wall or the tub deck where the faucet components are installed. They serve both an aesthetic purpose and a practical one, concealing the plumbing connections and preventing water from seeping behind the wall or into the tub deck. Escutcheons are typically made of metal or plastic and are available in a variety of styles and finishes to match the faucet. They are usually attached to the faucet components with screws or other fasteners. Damaged or missing escutcheons can detract from the appearance of the faucet and can also allow water to leak into the wall or tub deck.

O-Rings: These are small, circular rubber seals that are used to prevent leaks around the various connections in the faucet. They are typically located around the valve stems, cartridges, and spout connections. O-rings can degrade over time due to exposure to water, chemicals, and temperature fluctuations. When O-rings fail, they can cause leaks. Replacing the O-rings is a common and relatively inexpensive repair for bathtub faucets. It is important to use O-rings that are specifically designed for plumbing applications, as other types of O-rings may not be resistant to water and chemicals.

Supply Lines: These are flexible or rigid pipes that connect the faucet valve bodies to the water supply lines. They are typically made of copper, stainless steel, or PEX. Flexible supply lines are easier to install than rigid pipes, but they are also more prone to leaks. Supply lines should be inspected periodically for signs of wear or damage. Leaks in the supply lines can cause significant water damage if not addressed promptly. Replacing the supply lines is a relatively straightforward process, but it requires shutting off the water supply to the faucet.

Understanding the various components of a bathtub faucet, their functions, and potential issues is crucial for effective troubleshooting and repair. While some repairs, such as replacing washers or cartridges, can be performed by homeowners, more complex repairs, such as replacing valve bodies or diverter mechanisms, may require the expertise of a professional plumber. Identifying the specific parts and communicating effectively with a plumber will ensure that the correct repairs are made and that the faucet is restored to proper working order.

Learn How To Remove And Install Various Tub Spouts

Parts Of A Bathtub With Diagram Homenish

Bathtub Parts Everyone Should Know About Part Names 2024

Parts Of Shower Valve Name Diagram Linquip

Ultimate Guide On 24 Parts Of A Bathtub Names Functions Diagram

Valley Back To Tub Shower Replacement Parts

Bath Tub Spouts The Largest Selection Of On Web

Shower Valve Types 101 How To Choose The Right Vevano

Learn How To Remove And Install Various Tub Spouts

T S Brass B 3201 Shower Valve Parts Breakdown Kullysupply Com

Related Posts