```html

Resurfacing Fiberglass Bathtubs: A Comprehensive Guide

Fiberglass bathtubs offer a cost-effective and lightweight alternative to traditional materials like cast iron or steel. However, over time, the gel coat surface of a fiberglass bathtub can become dull, stained, scratched, or cracked. Rather than replacing the entire tub, resurfacing provides a viable option to restore its appearance and extend its lifespan. This article provides a comprehensive guide to understanding the process of resurfacing fiberglass bathtubs, outlining the key considerations, steps involved, and expected outcomes.

Resurfacing, also known as refinishing or reglazing, involves applying a new coating to the existing bathtub surface. This coating bonds to the original finish, creating a fresh, durable, and aesthetically pleasing surface. The process is typically more affordable and less disruptive than a full bathtub replacement, which often necessitates plumbing and tile work. While DIY kits are available, professional resurfacing generally yields superior and longer-lasting results due to the use of specialized equipment, materials, and expertise.

Understanding the Condition of the Bathtub

Before embarking on a resurfacing project, a thorough assessment of the bathtub's condition is crucial. Minor scratches, stains, and dullness are easily addressed with resurfacing. However, structural damage, such as significant cracks that extend deep into the fiberglass or widespread delamination of the gel coat, may necessitate more extensive repairs or even replacement. Identifying the extent of the damage dictates the appropriate course of action. Deep cracks might require patching with fiberglass repair compounds before the actual resurfacing process begins. Ignoring underlying structural issues will compromise the longevity and effectiveness of the new surface coating. A professional inspection can accurately determine the tub's suitability for resurfacing and identify any hidden problems.

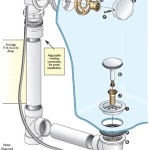

Furthermore, the existing plumbing fixtures, such as the drain and overflow, should be evaluated. Often, these are removed or masked during the resurfacing process. If they are significantly corroded or damaged, it may be prudent to replace them concurrently with the resurfacing project to ensure a seamless and aesthetically consistent finished product. The age and type of caulk surrounding the bathtub should also be considered. Old or crumbling caulk needs to be removed and replaced to prevent water damage and mold growth, both of which can undermine the integrity of the resurfaced tub.

The Resurfacing Process: A Step-by-Step Overview

The resurfacing process typically involves several key steps, each designed to ensure optimal adhesion and a durable finish. These steps include surface preparation, masking and protection, application of bonding agents, spraying of the new coating, and final curing and polishing.

Surface Preparation: This is perhaps the most critical stage. The existing surface must be thoroughly cleaned and abraded to create a suitable profile for the new coating to adhere to. This involves removing soap scum, mineral deposits, and any loose or flaking material. Abrasive cleaners, degreasers, and specialized etching solutions are commonly used. Sanding with progressively finer grits of sandpaper further roughens the surface, creating microscopic grooves that enhance bonding. The surface must be completely dry and free of any contaminants before proceeding.

Masking and Protection: Protecting surrounding surfaces from overspray is essential. The walls, flooring, and any fixtures that cannot be removed are carefully masked with plastic sheeting and painter's tape. Proper ventilation is also crucial, as the chemicals used in the resurfacing process can emit strong fumes. Professional resurfacers typically use exhaust fans to remove these fumes and ensure a safe working environment.

Application of Bonding Agents: A bonding agent or primer is applied to the prepared surface to further promote adhesion between the old and new coatings. This agent acts as an intermediary, creating a chemical bridge that strengthens the bond and prevents peeling or chipping. The specific type of bonding agent used depends on the existing surface and the type of coating being applied.

Spraying of the New Coating: The new coating, typically a specialized epoxy acrylic or polyurethane, is applied using a high-volume, low-pressure (HVLP) sprayer. Multiple thin coats are applied to achieve a uniform and durable finish. The sprayer allows for precise control over the coating thickness and ensures a smooth, even application. The color of the new coating can be customized to match the existing bathroom decor or to create a new aesthetic.

Curing and Polishing: After the coating has been applied, it needs to cure completely. This process can take anywhere from 24 to 72 hours, depending on the specific product used and the ambient temperature. During this time, the bathtub should not be used. Once the coating is fully cured, it may be lightly polished to remove any imperfections and enhance the shine. The masking is then removed, and new caulk is applied around the edges of the bathtub.

Factors Influencing Cost and Durability

The cost of resurfacing a fiberglass bathtub can vary depending on several factors, including the size and condition of the bathtub, the type of coating used, and the location. Generally, professional resurfacing is more expensive than DIY kits, but the results are typically superior in terms of both appearance and longevity. The durability of the resurfaced bathtub is also influenced by several factors, including the quality of the materials used, the skill of the applicator, and the maintenance practices of the homeowner.

The choice of coating material significantly impacts durability. Epoxy acrylics and polyurethanes are commonly used due to their resistance to chipping, scratching, and staining. However, some formulations are more durable than others. A higher solids content generally indicates a more durable and longer-lasting coating. It's important to discuss the available options with the resurfacing professional and choose a coating that meets the specific needs and budget.

Proper maintenance is crucial for extending the life of a resurfaced bathtub. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the coating. Instead, mild soaps and detergents should be used for cleaning. It's also important to avoid dropping heavy objects into the bathtub, as this can cause chipping or cracking. Regularly cleaning and drying the bathtub after each use can help prevent soap scum buildup and maintain its appearance.

The expertise of the technician performing the resurfacing greatly influence the final quality. Experienced technicians understand the nuances of surface preparation, proper mixing ratios of chemicals, even application of the coating, and optimal curing conditions. A poorly executed resurfacing job can result in premature peeling, bubbling, or discoloration. Choosing a reputable and experienced resurfacing company is a critical investment in the longevity of the final product.

In addition to the points mentioned above, the environment in which the resurfacing takes place can impact the durability. High humidity or extreme temperatures during the application and curing phases can negatively affect the adhesion and overall performance of the coating. A temperature-controlled environment, while not always possible, can greatly improve the outcome of the resurfacing process.

```

Can Plastic Acrylic Or Fiberglass Bathtubs Shower Stalls Be Reglazed Refinished America Refinishing Pros

How To Refinish Your Bathtub For 50

Can A Fiberglass Bathtub Be Refinished Todd S Bathtubs

How Long Does Reglazing A Bathtub Last

Tub Resurfacing Ballpark Estimator Custom And Tile

Bathtub Reglazing Todds Porcelain Fiberglass Repair

How To Paint A Bathtub Yourself The Nifty Nester

Shower Refinishing Reglazing Specialized Co

How To Paint A Tub Shower Surround Before After Fiberglass Refinishing Diy Power Couple

Fiberglass Tub Reglazing Bathroom In Massachusetts

Related Posts