How Bathtub Stoppers Work: A Comprehensive Guide

The seemingly simple act of filling a bathtub relies on a key component: the bathtub stopper. These devices, often overlooked in their everyday function, are responsible for creating a watertight seal that prevents water from draining prematurely, allowing individuals to enjoy a relaxing bath. While the concept is straightforward, the mechanism by which bathtub stoppers achieve this function varies depending on the type of stopper used. Understanding the inner workings of these stoppers can be insightful, especially when troubleshooting issues or selecting the right replacement.

Bathtub stoppers are designed to be easily operated and relatively durable. However, wear and tear, mineral deposits from hard water, and accumulated debris (hair, soap scum, etc.) can all contribute to their eventual failure. This article will explore the most common types of bathtub stoppers, detailing their construction, operation, and potential points of failure. By gaining a deeper understanding of these mechanisms, one can better appreciate the functionality and maintenance needs of this essential plumbing fixture.

Pop-Up Stoppers: A Lift and Seal Mechanism

Pop-up stoppers, also known as lift-and-turn stoppers or push-and-pull stoppers, are a prevalent type of bathtub drain closure. These stoppers are characterized by a visible cap or top that protrudes slightly from the drain opening. This cap is connected to a series of internal linkages that, when activated, either raise or lower the stopper to control water flow.

The core mechanism of a pop-up stopper relies on a simple lever system. Beneath the drain opening, a rocker arm connects to the stopper cap. This rocker arm pivots on a central point. When the stopper cap is pressed or lifted (depending on the design), the rocker arm moves, causing the stopper to either seat firmly against the drain opening, creating a seal, or lift away from the drain opening, allowing water to flow freely. The seal is usually formed by a rubber or silicone gasket located on the underside of the stopper cap.

The linkage usually extends horizontally underneath the tub to a pivot point. This pivot point is often connected to a handle or lever located on the overflow plate of the bathtub. Activating this handle or lever manipulates the rocker arm and subsequently the stopper. Some systems, particularly those activated by pushing the stopper cap, utilize a spring-loaded mechanism. Pushing the cap down compresses the spring and locks the stopper in the closed position. Pushing the cap again releases the spring, allowing the stopper to pop up and open the drain.

Common issues with pop-up stoppers include hair and debris accumulation around the rocker arm and the rubber gasket, preventing a proper seal. Mineral deposits can also stiffen the mechanism, making it difficult to operate. Disassembly and cleaning are usually required to resolve these problems. In some cases, the linkages themselves may become bent or broken, necessitating replacement of the entire stopper assembly.

Trip Lever Stoppers: Overflow Plate Activation

Trip lever stoppers are another common type of bathtub drain closure, differentiated by their reliance on an overflow plate located on the side of the tub. This overflow plate houses a lever, often a small knob or handle, that controls the drain stopper. This system provides a convenient way to open and close the drain without having to reach into the tub.

The mechanism of a trip lever stopper involves a vertical linkage that connects the trip lever to the stopper at the bottom of the drain. When the trip lever is moved to the "open" position, the linkage pulls the stopper upwards, allowing water to drain. Conversely, when the lever is moved to the "closed" position, the linkage lowers the stopper, creating a seal against the drain opening.

The stopper itself is typically a plunger-style design, often made of rubber or plastic. This plunger fits snugly into the drainpipe, creating a watertight seal when fully lowered. The effectiveness of the seal depends on the condition of the plunger and the cleanliness of the drainpipe. Any debris or imperfections in either component can compromise the seal and lead to leaks. The linkage connecting the trip lever to the plunger is often made of metal rods and pivots. These components are subject to corrosion and wear, which can lead to sticking or failure of the mechanism.

The position of the linkage is adjustable, offering some control over how tightly the stopper seals and how far it opens. Often, access to the adjustment point is through the overflow plate. Adjusting the linkage can compensate for wear and tear or minor misalignments, potentially extending the life of the stopper. However, if the linkage is severely corroded or damaged, replacement is generally the best course of action.

Common problems associated with trip lever stoppers include hair and debris accumulation around the plunger, corrosion of the linkage, and stretching or breaking of the connecting rods. The overflow plate and associated hardware can also become corroded or damaged, rendering the entire system inoperable.

Toe-Touch Stoppers: Foot-Activated Convenience

Toe-touch stoppers represent a more modern design, offering a hands-free operation for opening and closing the bathtub drain. These stoppers are activated by simply pressing down on the stopper cap with a toe or foot. This eliminates the need to bend over or reach for a lever, providing a convenient and hygienic solution.

The internal mechanism of a toe-touch stopper typically involves a spring-loaded core. When the stopper cap is pressed, it compresses the spring and engages a locking mechanism, usually a small pin or detent, that holds the stopper in the closed position. Pressing the cap again releases the locking mechanism, allowing the spring to decompress and pop the stopper up, opening the drain.

The sealing surface of a toe-touch stopper is generally a rubber or silicone gasket located on the underside of the stopper cap, similar to pop-up stoppers. The gasket's condition is crucial for maintaining a watertight seal. Any damage or debris on the gasket can prevent it from properly seating against the drain opening, leading to leaks. The locking mechanism is comprised of small, intricate parts. These parts are susceptible to wear and tear, and the accumulation of debris can interfere with their function.

These stoppers generally come in two types: lift-and-turn and push-and-seal. The lift-and-turn toe-touch stopper requires one to push the top to seal and then turn to lock in place. The push-and-seal is similar to a ball-point pen, where pushing it once seals and pushing it again releases the sealing.

While toe-touch stoppers are convenient, they can be prone to certain issues. Hair and debris can easily become trapped around the stopper cap and within the internal mechanism, hindering its operation. The spring can lose its tension over time, making it difficult to pop the stopper open. The locking mechanism can also fail, causing the stopper to either remain stuck in the closed position or fail to seal properly. Disassembly, cleaning, and occasional lubrication can help to maintain the functionality of a toe-touch stopper. In some cases, however, replacement is necessary.

Flip-It Stoppers: A Simple and Direct Approach

Flip-it stoppers represent a simpler, more direct approach to bathtub drain closure. These stoppers do not rely on complex linkages or internal mechanisms. Instead, they consist of a hinged stopper cap that physically flips to either cover or uncover the drain opening.

The flip-it stopper directly covers the drain opening. The stopper contains a rubber gasket underneath that creates the seal. The ease of use and installation makes this a popular replacement for many bathtubs. The design inherently makes the stopper less prone to hair and debris issues.

The simplicity of the flip-it stopper design also implies that there are fewer issues. The gasket itself can still deteriorate and the hinge can wear out. Some designs are universal and may not perfectly fit all drains. Despite its simplicity, the flip-it stopper offers a functional and relatively maintenance-free solution for controlling bathtub drainage.

Although effective, the flip-it stopper needs to be sized correctly and installed according to its requirements. Most designs are made to fit an already existing drain fixture, so careful inspection before installation is necessary. Correct installation allows the gasket to fully seal and prevent drainage.

Each of these stopper types provide a unique approach to sealing a bathtub drain. Understanding the specific mechanism, the potential points of failure, and the appropriate maintenance procedures can help to keep the system working and prevent costly plumbing repairs.

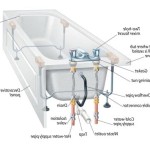

How A Bathtub Works Types Plumbing Diagrams Hometips

How To Fix A Bathtub Or Sink Pop Up Stopper

Drain Overflow Assemblies Fine Homebuilding

How To Replace Bathtub Drain Stopper With A Lift And Turn Diy

Bathroom Fixtures How Do You Turn The Overfow Drain In Tub Upside Down Home Improvement Stack Exchange

The Diffe Parts Of A Bathtub And How They Work Family Handyman

7 Bathtub Plumbing Installation Drain Diagrams

How To Remove A Bathtub Drain The Home Depot

How Does A Bathtub Drain Work

How To Work Bathtub Cable Drain Hofen