Concrete Bathtub Mold: Essential Aspects to Consider

Concrete bathtubs, renowned for their durability, unique aesthetics, and customizable nature, have gained increasing popularity in modern bathroom designs. Creating a concrete bathtub involves utilizing a mold, a crucial element that shapes and defines the final product. This article delves into the essential aspects of concrete bathtub mold, exploring its materials, benefits, considerations, and best practices.

Materials for Concrete Bathtub Mold

The choice of material for a concrete bathtub mold significantly impacts the quality and longevity of the final product. Common materials used include:

- Fiberglass: Fiberglass molds are lightweight, durable, and provide a smooth surface finish. However, they can be more expensive than other options.

- Plastic: Plastic molds, particularly polyethylene or ABS plastic, offer flexibility, durability, and affordability. They are also relatively easy to clean and maintain.

- Wood: Wood molds, typically made from marine-grade plywood or MDF, are inexpensive and can be customized to create unique shapes. However, they require sealing and reinforcement to withstand moisture and concrete weight.

Benefits of Using Concrete Bathtub Mold

Utilizing a concrete bathtub mold offers several advantages:

- Consistency and Precision: Molds ensure consistent shape, size, and dimensions of the concrete bathtub, eliminating variations and ensuring a high-quality finished product.

- Customizable Designs: Molds allow for the creation of custom and unique bathtub designs, enabling the realization of specific stylistic preferences or design requirements.

- Enhanced Durability: Concrete bathtubs cast in molds exhibit increased strength and durability, as the mold provides support and prevents deformation during the curing process.

Considerations for Bathtub Mold Selection

When selecting a concrete bathtub mold, several factors should be considered:

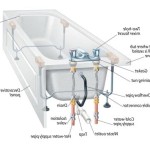

- Bathtub Size and Shape: The mold should accommodate the desired dimensions and shape of the concrete bathtub, including its length, width, depth, and any decorative elements.

- Mold Material Durability: The mold's material should be capable of withstanding the weight of the concrete and the casting process without compromising its shape or integrity.

- Release Agent Compatibility: The mold should be compatible with the release agent used to facilitate the removal of the concrete bathtub from the mold after the curing process.

Best Practices for Using Concrete Bathtub Mold

To ensure the successful casting and creation of a concrete bathtub using a mold, certain best practices should be followed:

- Prepare the Mold Surface: Before casting the concrete, apply a release agent to the mold's interior surfaces to prevent the concrete from sticking.

- Pour Concrete Slowly: Pour the concrete mixture into the mold gradually, ensuring that it fills the mold evenly and without creating air pockets.

- Tap and Vibrate the Mold: Gently tap or vibrate the mold to release any trapped air and ensure proper compaction of the concrete.

- Cure Properly: Allow the concrete to cure inside the mold for the recommended duration, typically several days, to ensure complete strength development.

Conclusion

Concrete bathtub mold plays a vital role in shaping and defining the final product. By understanding the materials, benefits, considerations, and best practices associated with concrete bathtub mold, individuals can make informed decisions and ensure the successful creation of a durable, visually appealing, and long-lasting concrete bathtub.

Guide To Bathtub Materials Concrete Diy Mold In Bathroom

Bathtub Bañera De Cemento Baño Tinas

Concrete Bathtub

Concrete Bathtub An Artistic Marvel For Your Bathroom In 2024

Making A Concrete Bath Tub Part 2 Mold Removal And Finishing

Pour It Yourself Concrete Bath An Award Winner Stuff Co

Cocoon Concrete Tub Collection

How To Pour Concrete Bathtubs Hunker

Concrete Bath Custom Freestanding Handmade 1 9m Large

Making A Concrete Bath Tub Part 1 Setup