Understanding Bathtub Door Hardware: A Comprehensive Guide

Bathtub door hardware encompasses all the components necessary for the smooth operation and secure functionality of bathtub doors. These elements, often overlooked, play a crucial role in the longevity and usability of the enclosure. Understanding the various types of hardware, their functions, and potential issues can aid in informed decision-making during installation, maintenance, and replacement.

The selection of appropriate bathtub door hardware is paramount for ensuring a comfortable and safe bathing experience. The hardware should be chosen based on the type of door (sliding, pivoting, folding), the design and weight of the glass or material used, and the overall aesthetic of the bathroom. Compromising on quality can lead to premature wear, operational difficulties, and potential safety hazards.

Types of Bathtub Door Hardware

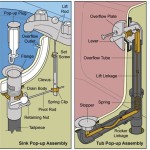

Bathtub door hardware can be broadly categorized into several key components, each with specific roles and features. These include rollers, hinges, handles, tracks, and seals.

Rollers: Rollers are primarily used in sliding bathtub doors. These components allow the doors to glide smoothly along the track. Rollers are typically constructed from materials like nylon, brass, or stainless steel. The quality of the rollers directly impacts the ease of operation and the noise level. Higher-quality rollers often feature stainless steel ball bearings for improved durability and smoother movement. Regular cleaning and lubrication are essential to prevent corrosion and ensure optimal performance. Over time, rollers can wear down, leading to sticking or difficulty in sliding the door. Replacement rollers are readily available, making it a relatively simple maintenance task.

Hinges: Hinges are essential for pivoting or swinging bathtub doors. They provide the pivotal point around which the door rotates. Hinges are typically made from solid brass or stainless steel to withstand constant exposure to moisture and humidity. The design of the hinge can vary significantly, from basic butt hinges to more elaborate offset or pivot hinges. The choice of hinge depends on the weight of the door and the desired aesthetic. Properly installed and maintained hinges ensure smooth opening and closing of the door and prevent sagging or misalignment. Over time, hinges can corrode or become loose, requiring tightening or replacement.

Handles: Handles provide a grip for opening and closing the bathtub door. They are available in a wide variety of styles, materials, and finishes. Common materials include stainless steel, brass, chrome, and acrylic. The handle should be ergonomically designed for comfortable use and should complement the overall style of the bathroom. Beyond aesthetics, the handle must be securely attached to the door. Loose or broken handles pose a safety risk. Some handles may also incorporate integrated towel bars for added functionality. The choice of handle is often a matter of personal preference, but durability and ease of cleaning should be considered.

Tracks: Tracks are the rails along which sliding bathtub doors move. They are typically made from aluminum or stainless steel and are designed to provide a smooth and level surface for the rollers. The design of the track impacts the stability and ease of operation of the sliding door. Tracks should be easy to clean to prevent the build-up of soap scum and grime. Regular cleaning helps maintain smooth roller movement and prevents corrosion. Damaged or bent tracks can cause the door to stick or derail. Depending on the severity of the damage, the track may need to be repaired or replaced.

Seals: Seals are installed along the edges of the bathtub door to prevent water from leaking out. They are typically made from flexible materials like vinyl or silicone. Effective seals are crucial for maintaining a dry and safe bathroom environment. Over time, seals can degrade due to exposure to moisture, soap, and chemicals. Cracked or brittle seals should be replaced promptly to prevent water damage. Seals are available in a variety of shapes and sizes to fit different types of bathtub doors. Selecting the correct type of seal is essential for achieving a watertight closure. Some seals also incorporate magnetic strips for enhanced sealing performance.

Factors Influencing Hardware Selection

Several crucial factors influence the selection of suitable bathtub door hardware. These considerations extend beyond aesthetics and encompass the functional requirements and environmental conditions of the bathroom space.

Material: The material composition of the hardware significantly impacts its durability and resistance to corrosion. Stainless steel and solid brass are generally considered superior choices due to their inherent resistance to rust and degradation in humid environments. Chrome-plated finishes can provide a visually appealing alternative, but the underlying material's quality is still important. Aluminum is lightweight and resistant to corrosion, making it suitable for certain components like tracks. The material should be selected based on the expected lifespan and exposure to water and cleaning agents.

Door Type: Different types of bathtub doors require different types of hardware. Sliding doors necessitate rollers and tracks, while pivoting doors require hinges. Folding doors may utilize a combination of hinges and rollers. The hardware must be specifically designed for the intended door type to ensure proper operation and stability. Using the wrong type of hardware can lead to premature wear, operational difficulties, and potential safety hazards. The weight and size of the door must also be taken into account when selecting the appropriate hardware. Heavier doors require more robust hardware to prevent sagging or misalignment.

Finish: The finish of the hardware contributes to the overall aesthetic of the bathroom. Common finishes include chrome, brushed nickel, oil-rubbed bronze, and matte black. The finish should complement the other fixtures and fittings in the bathroom. The finish should also be durable and resistant to scratches and tarnishing. Some finishes are more susceptible to water spots and fingerprints, requiring more frequent cleaning. The choice of finish is ultimately a matter of personal preference, but durability and ease of maintenance should be considered.

Weight of the Door: The weight of the bathtub door is a critical factor in determining the appropriate hardware. Heavier doors require more robust hardware. Hinges and rollers must be rated to support the weight of the door to prevent sagging or premature wear. Using inadequate hardware can lead to operational difficulties and potentially dangerous situations. The manufacturer's specifications should be carefully reviewed to ensure that the hardware is suitable for the weight of the door.

Installation Considerations: Proper installation is essential for ensuring the longevity and performance of the bathtub door hardware. The hardware should be installed according to the manufacturer's instructions. Incorrect installation can lead to operational difficulties, water leaks, and potential safety hazards. It is often advisable to hire a professional installer to ensure that the hardware is installed correctly. The installer should have experience with bathtub door hardware and should be familiar with local building codes. Before installation, the wall or frame should be checked for plumb and level to ensure proper alignment of the door.

Maintenance and Troubleshooting

Regular maintenance is crucial for extending the lifespan and ensuring the optimal performance of bathtub door hardware. Common maintenance tasks include cleaning, lubrication, and inspection. Timely troubleshooting can prevent minor issues from escalating into major problems.

Cleaning: Regular cleaning is essential for removing soap scum, grime, and mildew from the hardware. A mild soap and water solution is generally sufficient for cleaning most types of hardware. Abrasive cleaners should be avoided as they can damage the finish. Hard water stains can be removed with a solution of vinegar and water. The hardware should be thoroughly rinsed and dried after cleaning. Regular cleaning helps prevent corrosion and maintains the aesthetic appearance of the hardware. Special attention should be paid to areas that are prone to water accumulation, such as tracks and seals.

Lubrication: Lubrication helps ensure smooth operation of rollers and hinges. A silicone-based lubricant is recommended as it will not attract dust or grime. The lubricant should be applied sparingly to the moving parts of the hardware. Regular lubrication prevents sticking, squeaking, and premature wear. Over-lubrication should be avoided as it can attract dust and grime and worsen the problem. The lubricant should be reapplied as needed, depending on the frequency of use and environmental conditions.

Inspection: Regular inspection helps identify potential problems before they become major issues. The hardware should be inspected for signs of corrosion, wear, and damage. Loose screws should be tightened, and worn or damaged parts should be replaced promptly. The seals should be inspected for cracks and brittleness. The alignment of the door should be checked to ensure that it is closing properly. Early detection of problems can prevent costly repairs and ensure the safety of the bathroom.

Troubleshooting Common Issues: Several common issues can arise with bathtub door hardware, including sticking rollers, squeaky hinges, and leaky seals. Sticking rollers can often be resolved by cleaning and lubricating the tracks and rollers. Squeaky hinges can be lubricated or tightened. Leaky seals should be replaced promptly to prevent water damage. If the problem persists, it may be necessary to consult with a professional installer.

Understanding the different types of bathtub door hardware, the factors influencing hardware selection, and the importance of regular maintenance can contribute to a more informed and satisfying bathroom experience. Investing in quality hardware and adhering to proper maintenance practices can ensure the longevity and optimal performance of the bathtub door for years to come.

Delta Lyndall 20 In Shower And Bathtub Door Handles Oil Rubbed Broe 2 Pack Sdbr008 Ob R The Home Depot

Sunny 58 5 60 W X 62 H Sliding Door Tub Glass Shower For 1 4 Satin Showers

Streamline Malone 60 In W X 58 Sliding Bathtub Door Crystaltech Treated 5 16 Tempered Clear Glass Polished Chrome Hardware Aq 240 Ch R The Home Depot

Ckb Single Sliding Frameless Bathtub Shower Doors 55 59 Inch Width Adjustable X 60 Height 5 16 Tempered Glass With Hardware Kit Com

Vigo Elan 65 5 In X 60 Frameless Bypass Sliding Matte Black Bathtub Door Clear Glass Vg6041mbcl6066 Rona

Elegant 60 X 62 Semi Frameless Sliding Shower Tub Door Bypass Black Hardware

Glass Warehouse Astro Satin Brass 52 In To 56 X 60 Frameless Sliding Bathtub Door The Doors Department At Com

Vigo Elan 66 In X 56 To 60 Frameless Bypass Sliding Stainless Steel Bathtub Door Clear Glass Vg6041stcl6066 Réno Dépôt

Paxos 8mm Bathtub Door Delta Shower Doors

Delavin Frameless Bathtub Door 56 60 In W X 59 H Clear Glass Gold Stainless Steel Com

Related Posts