Delta Bathtub Drain Assembly: A Comprehensive Guide

The bathtub drain assembly is a crucial component of any bathroom, responsible for efficiently removing water from the tub while preventing debris from entering the plumbing system. A well-functioning drain assembly ensures a pleasant bathing experience and avoids potential water damage to the bathroom. Delta Faucet Company, a prominent manufacturer of plumbing fixtures, offers a range of bathtub drain assemblies designed for durability, performance, and ease of installation. This article provides a detailed overview of Delta bathtub drain assemblies, covering their different types, components, installation process, common issues, and maintenance tips.

Types of Delta Bathtub Drain Assemblies

Delta manufactures several types of bathtub drain assemblies to accommodate various bathtub designs and plumbing configurations. Understanding the differences between these types is essential for selecting the appropriate drain assembly for a specific application.

Pop-Up Drain Assemblies: Pop-up drains are among the most common types of bathtub drain assemblies. They operate using a plunger mechanism that is controlled by a lever or knob located on the overflow plate. When the lever is activated, the plunger moves up and down, opening and closing the drain. Delta pop-up drain assemblies are typically constructed from brass or stainless steel, ensuring corrosion resistance and longevity. These assemblies are available in a variety of finishes to match the bathroom's decor.

Lift-and-Turn Drain Assemblies: Lift-and-turn drain assemblies feature a stopper that is manually lifted and turned to open or close the drain. This type of drain assembly is simple to operate and generally requires fewer parts than pop-up drains, making it a reliable option. Delta lift-and-turn drain assemblies are often made from durable materials like brass and are designed for easy installation and maintenance.

Toe-Touch Drain Assemblies: Toe-touch drain assemblies offer hands-free operation. A user can open or close the drain by simply pressing down on the stopper with their toe. This type of drain is particularly convenient for individuals with limited mobility. Delta toe-touch drain assemblies are designed with a spring-loaded mechanism that ensures a tight seal and prevents leaks.

Push-and-Seal Drain Assemblies: Push-and-seal drain assemblies provide a modern and sleek look. These assemblies feature a stopper that is pushed down to seal the drain and pushed again to release it. Delta push-and-seal drain assemblies are known for their ease of use and streamlined design. They are often available in a variety of finishes to complement contemporary bathroom styles.

Cable-Operated Drain Assemblies: Cable-operated drain assemblies use a cable to connect the overflow lever to the drain stopper. This type of drain assembly is suitable for bathtubs with more complex plumbing configurations or when the overflow is located at a distance from the drain. Delta cable-operated drain assemblies offer flexibility and reliability, even in challenging installation environments.

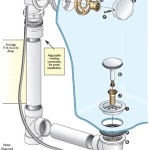

Components of a Delta Bathtub Drain Assembly

Regardless of the specific type, a typical Delta bathtub drain assembly consists of several key components that work together to ensure proper drainage and prevent leaks. Familiarity with these components is essential for installation, troubleshooting, and maintenance.

Drain Flange: The drain flange is the visible metal ring that sits flush with the bathtub's drain opening. It provides a secure connection point for the drain assembly and prevents water from leaking between the tub and the drain. Delta drain flanges are typically made from brass or stainless steel and are available in various finishes.

Drain Body: The drain body is the main housing of the drain assembly, connecting the drain flange to the drainpipe. It typically includes internal threads for securing the drain flange and a threaded outlet for connecting to the waste and overflow pipe. Delta drain bodies are designed for durability and corrosion resistance.

Stopper: The stopper is the component that seals the drain opening to prevent water from escaping. The design of the stopper varies depending on the type of drain assembly. Pop-up drains have a plunger-style stopper, while lift-and-turn drains have a stopper that is manually lifted and turned. Toe-touch and push-and-seal drains feature a specialized stopper mechanism.

Overflow Plate and Lever: The overflow plate is a decorative cover located near the top of the bathtub that conceals the overflow pipe. The overflow lever, which is attached to the overflow plate, controls the drain stopper in pop-up drain assemblies. Delta overflow plates and levers are available in a variety of finishes to match the bathroom's decor.

Waste and Overflow Pipe: The waste and overflow (W&O) pipe is a crucial component that connects the bathtub drain to the main drainpipe. It allows excess water to drain when the bathtub is overfilled, preventing overflows and potential water damage. Delta W&O pipes are typically made from PVC or brass and are designed for efficient drainage.

Gaskets and Washers: Gaskets and washers are used to create watertight seals between the different components of the drain assembly. These components are essential for preventing leaks and ensuring proper drainage. Delta drain assemblies typically include high-quality gaskets and washers made from rubber or silicone.

Installing a Delta Bathtub Drain Assembly

Installing a Delta bathtub drain assembly correctly is crucial for ensuring its proper function and preventing leaks. While professional installation is always recommended, a homeowner with intermediate plumbing skills can often complete the installation process by following these steps:

Preparation: Before beginning the installation, gather all necessary tools and materials, including a pipe wrench, adjustable wrench, screwdriver, plumber's putty, Teflon tape, and the new Delta bathtub drain assembly. Ensure the water supply to the bathroom is turned off.

Removing the Old Drain Assembly: Carefully remove the old drain assembly by loosening the drain flange with a pipe wrench or adjustable wrench. Disconnect the waste and overflow pipe from the drain body. Clean the drain opening thoroughly to remove any debris or old plumber's putty.

Preparing the Drain Flange: Apply a generous amount of plumber's putty to the underside of the new drain flange. This will create a watertight seal between the flange and the bathtub. Ensure the putty is evenly distributed around the flange.

Installing the Drain Flange: Insert the new drain flange into the drain opening, pressing firmly to ensure the plumber's putty makes good contact with the bathtub surface. From underneath the tub, attach the drain body to the drain flange, tightening it securely with a wrench. Remove any excess plumber's putty from around the flange.

Connecting the Waste and Overflow Pipe: Attach the waste and overflow pipe to the drain body, ensuring all connections are tight and secure. Use Teflon tape on the threaded connections to prevent leaks. If necessary, adjust the length of the waste and overflow pipe to fit the specific plumbing configuration.

Installing the Overflow Plate and Lever: Install the overflow plate and lever, connecting the lever to the drain stopper mechanism. Ensure the lever operates smoothly and the stopper seals the drain effectively. Secure the overflow plate to the bathtub with screws.

Testing for Leaks: After completing the installation, turn the water supply back on and fill the bathtub with water. Check for leaks around the drain flange, waste and overflow pipe, and overflow plate. If any leaks are detected, tighten the connections or reapply plumber's putty or Teflon tape as needed.

Common Issues with Delta Bathtub Drain Assemblies

Even with proper installation and maintenance, Delta bathtub drain assemblies can sometimes experience issues that affect their performance. Being aware of these common problems can help in troubleshooting and resolving them effectively.

Slow Drainage: Slow drainage is a common issue that can be caused by hair, soap scum, or other debris clogging the drainpipe. To resolve this, use a drain snake or plunger to clear the blockage. Regularly cleaning the drain with a drain cleaner can also help prevent clogs.

Leaks: Leaks can occur around the drain flange, waste and overflow pipe, or overflow plate. These leaks are often caused by loose connections, worn gaskets, or damaged pipes. Tightening the connections, replacing the gaskets, or repairing the damaged pipes can resolve the leaks.

Stopper Malfunction: The drain stopper may fail to seal properly, allowing water to leak out of the bathtub. This can be caused by a misaligned stopper, a worn stopper seal, or a malfunctioning lever mechanism. Adjusting the stopper, replacing the seal, or repairing the lever mechanism can fix the problem.

Corrosion: Over time, the metal components of the drain assembly can corrode due to exposure to water and chemicals. Corrosion can weaken the drain assembly and lead to leaks. Replacing the corroded components with new ones is the best solution.

Sticking or Difficulty Operating: The lever or stopper may become difficult to operate due to mineral buildup or corrosion. Cleaning the components with a descaling solution or lubricant can often restore smooth operation.

Maintaining a Delta Bathtub Drain Assembly

Regular maintenance is essential for extending the lifespan of a Delta bathtub drain assembly and preventing common issues. Simple maintenance tasks can help ensure the drain assembly functions properly for years to come.

Regular Cleaning: Regularly clean the drain flange and stopper to remove hair, soap scum, and other debris. Use a mild detergent and a soft brush to scrub the components clean. Avoid using harsh chemicals that can damage the finish.

Flushing the Drain: Periodically flush the drain with hot water to help dissolve any buildup of soap scum or grease. Pouring a pot of boiling water down the drain can also help clear minor clogs.

Checking for Leaks: Regularly check for leaks around the drain flange, waste and overflow pipe, and overflow plate. Address any leaks promptly to prevent water damage and further deterioration of the drain assembly.

Lubricating Moving Parts: Lubricate the moving parts of the drain assembly, such as the stopper mechanism and lever, with a silicone-based lubricant. This will help ensure smooth operation and prevent corrosion.

Replacing Worn Components: Replace any worn or damaged components, such as gaskets, washers, or stoppers, as needed. Using genuine Delta replacement parts will ensure compatibility and optimal performance.

Drain Assembly Metal Pop Up Bathroom In Chrome Rp5651 Delta Faucet

Drain Tub In Chrome Rp31558 Delta Faucet

Delta Foundations Series Pop Up Drain Assembly In Brushed Nickel Without Lift Rod Rp62472bn The Home Depot

Delta Bathtub Drains At Com

Delta Classic Toe Operated Bathwaste Assembly In Champagne Broe Rp693cz The Home Depot

Drain Tub In Chrome Rp31558 Delta Faucet

Delta Rp31558rb Venetian Broe Toe Operated Stopper Assembly For Rp693 Faucetdirect Com

Delta Rp31558ss Toe Operated Stopper Assembly For Rp693 Build Com

Delta Cable Action Bath Drain And Overflow Kit In Chrome Optof Ch D The Home Depot

Lift And Turn Bathtub Tub Drain Assembly Conversion Kit Trim Waste Single Hole Com